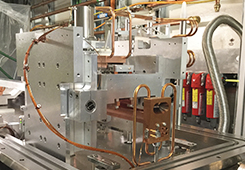

June 2016: Allectra Ltd recently supplied some water-cooled masks, scatter guard and cooling circuits for the new I02 Versatile Macromolecular X-tallography in-situ (VMXi) beamline under construction at the Diamond Light Source.

These water circuits were used to cool both multilayers of Diamonds new in-house designed Double Multilayer Monochromator (DMM). A further three water cooled masks were manufactured separately via the same processes to capture scattered radiation. VMXi is a phase 3 beamline upgrade which adds the DMM as a tool in addition to its current Double Crystal Monochromator (DCM). The new DMM is upstream of the DCM so the masks provide several functions:

Thermal stability from heating due to scattered radiation

Protection of internal DMM components from direct (white beam) and scattered beam

Protection of the downstream DCM from the diffracted DMM beam and any scattered radiation

The DMM is a critical part of VMXi and provides >60 times the flux (photons) at the sample compared to the DCM. This, combined with cutting edge fast capture X-ray detectors allows diffraction to be captured at room temperature before the sample decays. This is one of the first MX beamlines in the world to combine an undulator with a DMM.

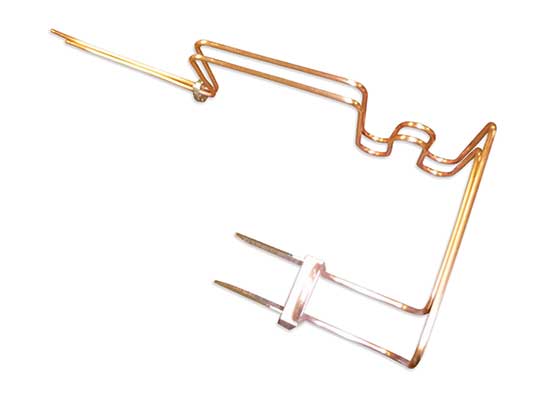

Allectra welcomed the challenge of manufacturing these parts where several different techniques were required of our skilled and experienced team. Brazing, welding, machining, pipe bending and plating were all used in the production of these components.

It was important for the customer that the cooling lines were manufactured from one continuous copper tube and the pipe bending was critical in order to achieve the tolerances the customer required. Projects like these that depend on innovation alongside expertise are always welcomed by Allectra as we walk away with experience which will serve our customers well in the future.

Allectra has recently installed a new CNC machine at the East Sussex facility to boost manufacturing capabilities due to increased demand for bespoke projects.

The engineering and workshop teams have been working on specialist solutions including a Tapered Flight Tube for an upgrade to the Tosca instrument at the Rutherford Appleton Laboratory, a Multi-Feedthrough flange for the National Synchrotron Radiation Research Center, Taiwan and new generation Microswitches for a European Fusion Experiment. Allectra has a second facility in Berlin with engineering and scientific capability which is also home to the R &D team.